Circular Design Collection

THE ASOS CIRCULAR DESIGN COLLECTION

Welcome to the ASOS Circular Design Collection!

The information on this homepage applies only to those products specifically identified as being part of the ASOS Design Circular Design Collection, and does not apply to 3rd party branded products.

Please note, products that meet our Circular Design Collection criteria only represent a small proportion of the total number of products at ASOS.

When you're browsing the ASOS Circular Design Collection, look for the 'About Me' drop down on the product’s page to see how that product meets our specified criteria for inclusion in the collection.

You may notice selected denim products that feature in the ASOS Circular Design Collection refer to the Ellen MacArthur Foundation’s 'The Jeans Redesign' - we will explain what this means in more detail below.

Circular design is an ever-evolving process, and the more we learn (from industry peers and thought leaders), the more we can refine our strategy. Keep scrolling down for more information about the ASOS Circular Design Collection: what ASOS means by the 'circular economy,’ 'circular design' and what ASOS’ circular design techniques are.

Please visit https://www.asos.com/discover/circular-design-key-definitions/ for an easy-to-read list of definitions of terms used throughout this page.

THE CIRCULAR ECONOMY

The circular economy is an alternative to the traditional linear economy of take, make, waste. In a circular economy, resources are kept in use, and circulated, for as long as possible. This can include initiatives such as reuse, repair, remanufacture and recycling. (1)

CIRCULAR DESIGN

It is important to note the difference between ‘designing for circularity’ (i.e. ‘circular design’) and a ‘circular product’. ASOS accepts that “...for a product to be truly ‘circular’, it also relies on the systems and infrastructure around it, as well as how the customer uses and disposes of it, not just the design of the product itself.”(2) Products within ASOS’ Circular Design Collection are not 'circular products’, rather they are designed with a selected set of circular design techniques in mind. Please note these design techniques do not address all aspects nor all parts of the product’s lifecycle, just those identified below and is therefore not supported by a full lifecycle assessment.

Please see below for a more detailed explanation of our Circular Design techniques and the criteria for inclusion in the ASOS Circular Design Collection.

ASOS’ approach to circular design is guided by the definitions and principles of leading industry organisations, such as the Ellen MacArthur Foundation and WRAP through its Textiles 2030 initiative .

THE ELLEN MACARTHUR FOUNDATION

The Ellen MacArthur Foundation is a charity committed to accelerating the transition to a circular economy.

ASOS has been a member of the Ellen MacArthur Foundation's Network since 2018 (please note that this is a membership which is paid for by ASOS). The Network brings together leaders from across the fashion industry to accelerate the transition to a circular economy in order to tackle challenges such as climate change, biodiversity loss, waste and pollution. By joining the Network, ASOS can access a variety of opportunities to accelerate change, such as learning tools, industry events and collaborative projects.

The Ellen MacArthur Foundation has defined a vision of a circular economy for the fashion and textile industry as one where products are (3):

Made to be used more

Made to be made again

Made from safe and recycled or renewable inputs

ASOS recognises the vision noted above to be the industry guiding principles of circular design for fashion and has informed the development of our design techniques for the ASOS Circular Design Collection.

ASOS also took part in the Ellen MacArthur Foundation’s 'The Jeans Redesign' from 2021 to its conclusion in 2023, which was an industry project by the Ellen MacArthur Foundation to show how jeans can be designed and made fit for a circular economy today. You can find out more information on The Jeans Redesign here: https://emf.thirdlight.com/link/1jxg1ysqnxil-mz55wp/@/

TEXTILES 2030

ASOS has also been a signatory to Textiles 2030 since 2021 (please note that ASOS pays a fee to be a signatory to this initiative).

This is a voluntary initiative by WRAP (a climate action NGO working around the globe to tackle the causes of the climate crisis), funded by its signatories and UK government. Signatories are working together to introduce more circular approaches to their businesses and contributing to discussions around policy development for textiles in the UK.

In 2023, Textiles 2030 released its Circular Design Toolkit, which was “created to establish a consistent set of circular design principles that the fashion and textile industry can align on, adapting them to suit their individual business needs and enabling the industry to accelerate progress towards circularity.”(4) ASOS has referred to this Circular Design Toolkit when creating the ASOS Circular Design Collection techniques.

CRITERIA FOR PRODUCTS TO BE INCLUDED IN ASOS CIRCULAR DESIGN COLLECTION

In 2023, we updated the ASOS Circular Design Collection criteria to align with guidance from the Textiles 2030 Circular Design Toolkit.

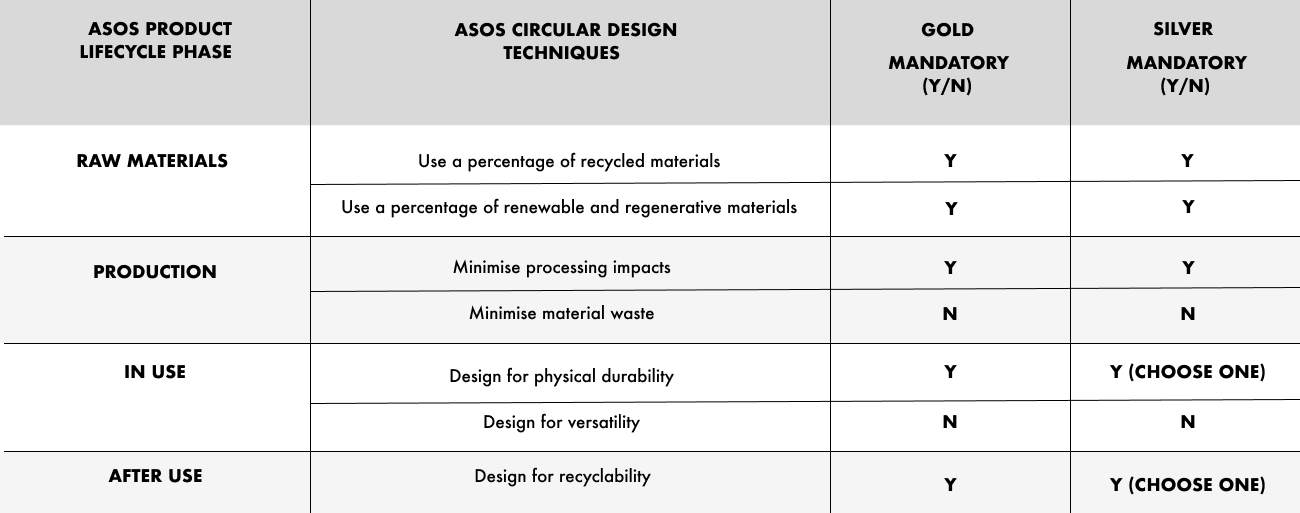

ASOS' definition of what constitutes circular design is underpinned by seven circular design techniques that can be applied across certain aspects of four phases of a product's lifecycle - we've illustrated a broad summary of this in the table below.

Ideally, a product that is designed to be fit for a circular economy at ASOS would use a combination of these techniques (as explained in further detail below) to address all four of the ASOS Product Lifecycle Phases. However, this may not always be feasible or technically possible and so we have split the requirements into a ‘Gold Standard’ and a ‘Silver Standard’, based on which/how many circular design techniques are achieved at each phase. The mandatory and optional techniques are shown in the table above.

Products must meet the Silver Standard as a minimum to be included in the ASOS Circular Design Collection. To achieve the Silver Standard, products must address both the Raw Materials and Production lifecycle phases and at least one other lifecycle phase (either In Use or After Use).

To achieve the Gold Standard, the product must address all four lifecycle stages (Raw Materials, Production, In Use and After Use) and the specified circular design techniques.

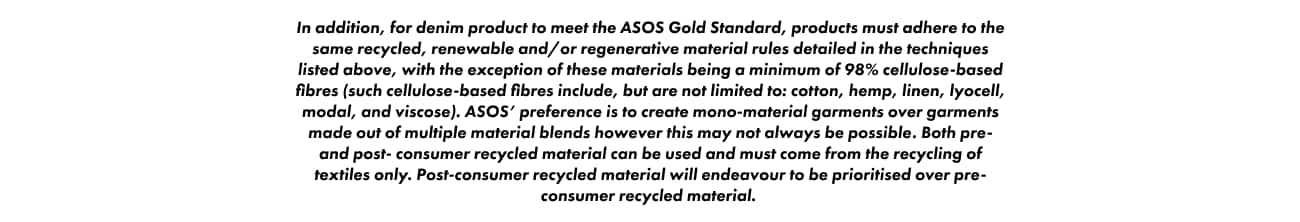

A note on denim: For a denim product to be included in the ASOS Circular Design Collection, it must at a minimum meet the Silver Standard requirements. However, our ‘Gold Standard’ for denim products is based on the minimum requirements of the Ellen MacArthur Foundation’s The Jeans Redesign Guidelines. We have explained below where the criteria in our Gold Standard differs for denim products to reflect The Jeans Redesign guideline requirements. Please note that the Ellen MacArthur Foundation do not verify that ASOS denim products meet their requirements.

Look for the 'About Me' drop down on the product’s page to see how the product meets our specified criteria for inclusion in the collection.

ASOS CIRCULAR DESIGN TECHNIQUES EXPLAINED

The ASOS Circular Design Collection Techniques (and where they differ for Gold Standard denim) are detailed below.

LIFECYCLE PHASE: RAW MATERIALS

ASOS' preference is for a product to be made of 100% recycled, renewable and/or regenerative materials, however this is not always possible. Therefore, all products within the ASOS Circular Design Collection must be made from a minimum of 98% recycled, renewable and/or regenerative materials by weight, in the total textile composition, with a 2% leeway for 'other' fibres. The total textile composition includes fabric, interlinings, pockets, and labels but excludes threads, zipper tape and hardware components. There is a minimum recycled fibre percentage (detailed below) that must be met, then the remaining fibre percentage within the product (if applicable) must come from a renewable or regenerative fibre source. Please also note that it is acceptable for the total textile composition of a product within the ASOS Circular Design Collection to be made from 100% recycled materials, therefore not using renewable or regenerative materials.

CIRCULAR DESIGN TECHNIQUE: TO USE A PERCENTAGE OF RECYCLED MATERIALS

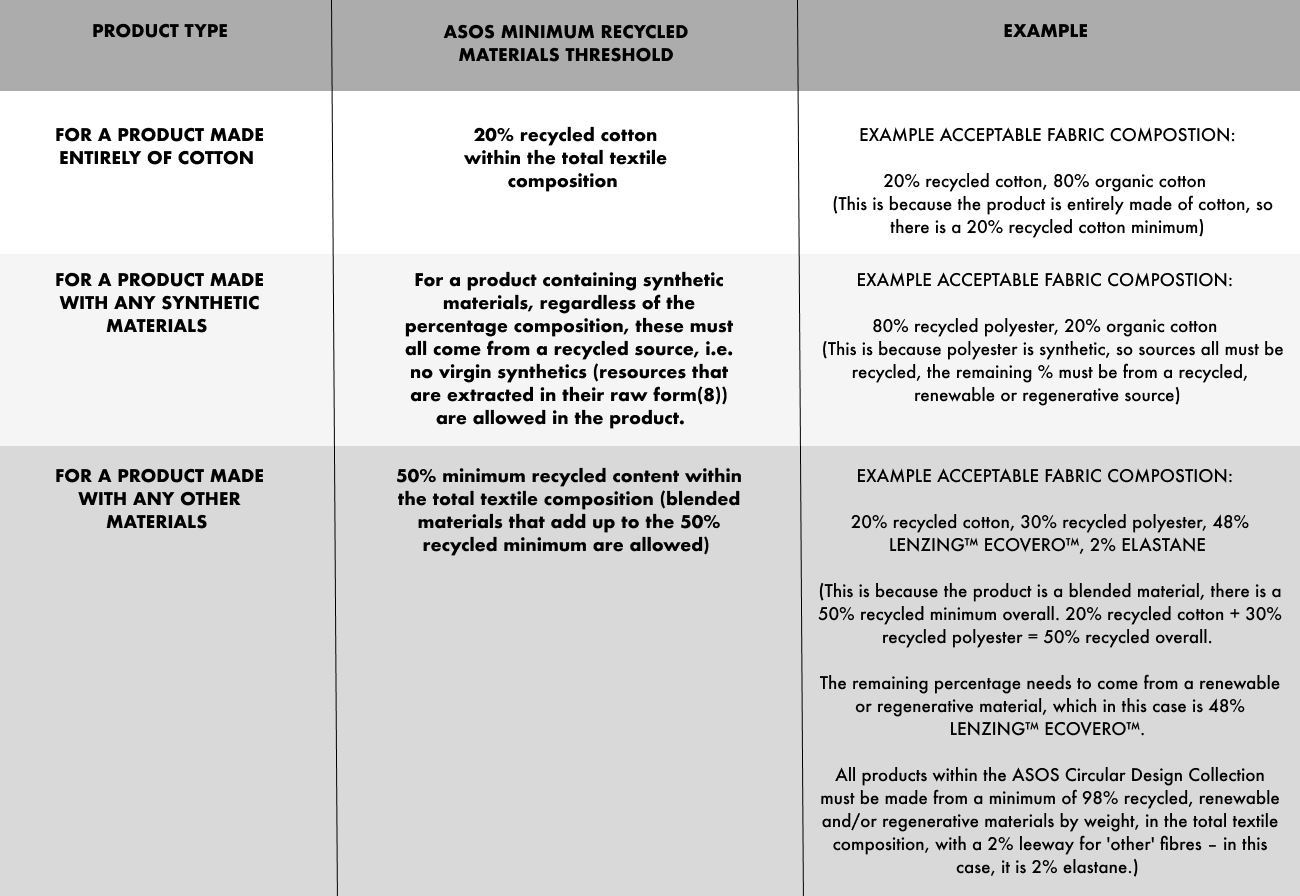

All products within the ASOS Circular Design Collection must contain a minimum recycled fibre percentage, which we have set out below.

It is important to note that Textiles 2030 state “the process (mechanical or chemical) that is used to create the recycled material can affect its quality, as some methods can damage the fibres more than others. Often, recycled content will need to be blended with virgin fibres (resources that are extracted in their raw form (5) to maintain the quality, durability and performance required, meaning it is currently difficult to source 100% recycled materials (6).” Therefore, ASOS has set minimum recycled fibre percentages for different materials, as detailed below, and in some cases allow blends with virgin renewable and/or regenerative fibres.

The total textile composition, by weight, must contain a minimum of 50% recycled content. Blends are permitted as long as the finished product contains at least 50% recycled content. Exceptions apply to:

Synthetics: for a product containing synthetics, these must all come from a recycled source, i.e. no virgin synthetics are allowed in the product.

Cotton: for a product made entirely of cotton, 20% of the product composition must be recycled cotton.

Both pre- and post- consumer recycled materials are accepted. The definition of recycled materials we refer to are (7):

Pre-consumer material: material diverted from the waste stream during the manufacturing process.

Post-consumer material: material generated by households or by commercial, industrial, and institutional facilities in their role as end-users of the product that can no longer be used for its intended purpose.

ASOS' RECYCLED MATERIALS MINIMUM PERCENTAGE THRESHOLDS

As explained above in more detail under our raw materials lifecycle phase, ASOS' preference is for a product to be made of 100% recycled, renewable and/or regenerative materials, however this is not always possible. Therefore, all products within the ASOS Circular Design Collection must be made from a minimum of 98% recycled, renewable and/or regenerative materials by weight, in the total textile composition, with a 2% leeway for 'other' fibres. The table below details ASOS’ recycled materials minimum percentage thresholds for inclusion within the ASOS Circular Design Collection:

CIRCULAR DESIGN TECHNIQUE: TO USE A PERCENTAGE OF RENEWABLE AND REGENERATIVE MATERIALS

This circular design technique applies once the recycled material content threshold noted above is achieved. The remaining product composition (if applicable), by weight, must be a renewable and/or regenerative material (e.g. organic cotton, regenerative cotton and branded viscose fibres).

The definitions of renewable and regenerative materials we refer to are:

A renewable material is made from a natural resource that can be replenished at a rate equal to or greater than the rate of depletion (9).

Regenerative materials are made using regenerative production practices, which build soil health and carbon content, increase water quality and biodiversity, and improve the resilience of ecosystems (10).

LIFECYCLE PHASE: PRODUCTION

There are many ways in which the environment is impacted at the production stage. We have focused in on two specific challenges only within our Circular Design Techniques – the use of wet processing and the minimisation of material waste (see above table regarding mandatory and optional techniques for a product’s inclusion within the Circular Design Collection).

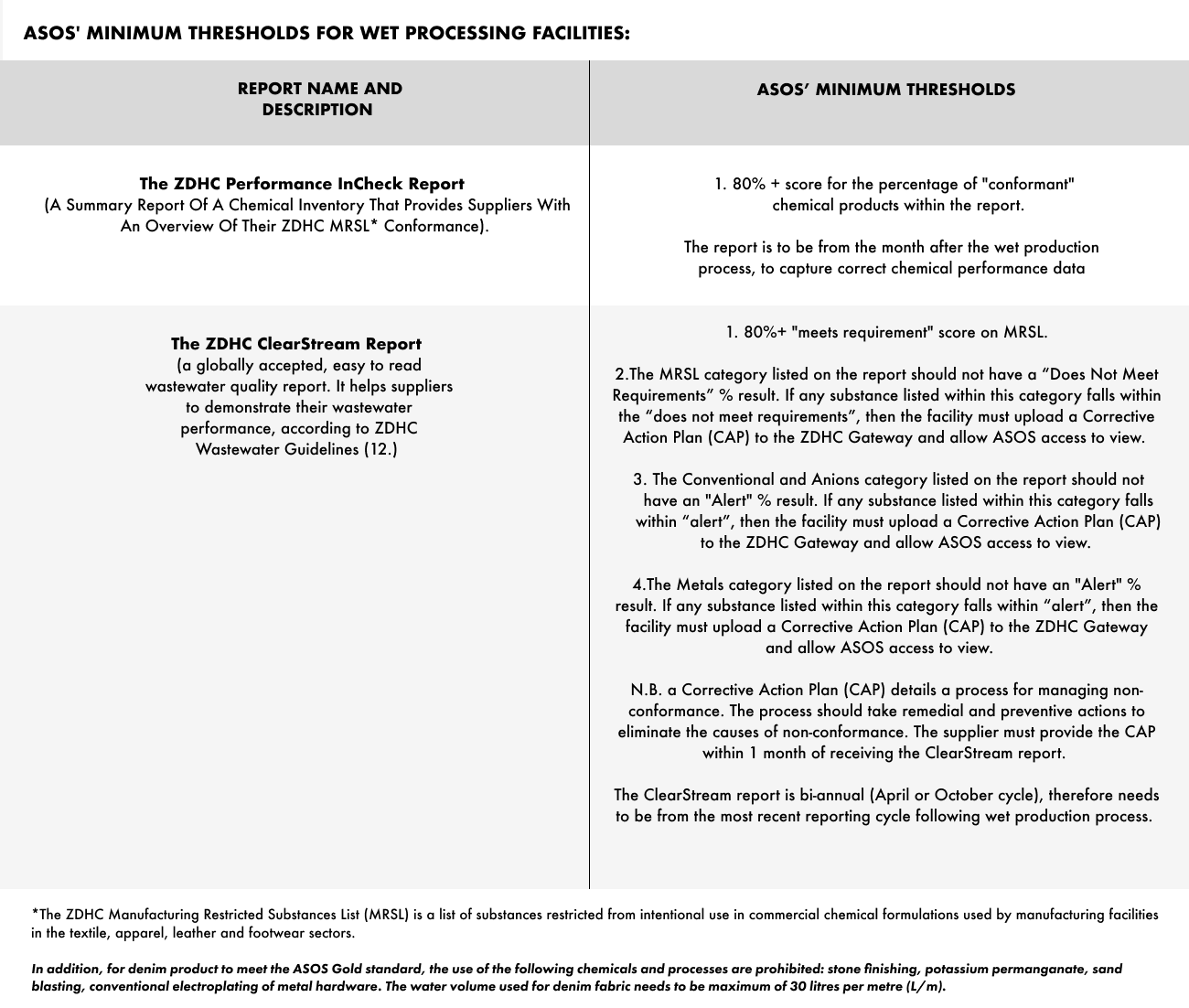

CIRCULAR DESIGN TECHNIQUE: MINIMISE PROCESSING IMPACTS

Any wet processing (liquid-based processes where textiles are treated with colourants and/or chemicals, this includes but is not limited to: dyeing, printing, laundry) facilities involved in production of products in the ASOS Circular Design Collection, must adhere to ASOS’ minimum requirements for the ZDHC (Zero Discharge of Hazardous Chemicals) Performance InCheck and ClearStream reports, which review “sustainable chemical management” (11) at facility level. ASOS joined the ZDHC Foundation’s Roadmap to Zero Programme in 2018.

CIRCULAR DESIGN TECHNIQUE: MINIMISE MATERIAL WASTE

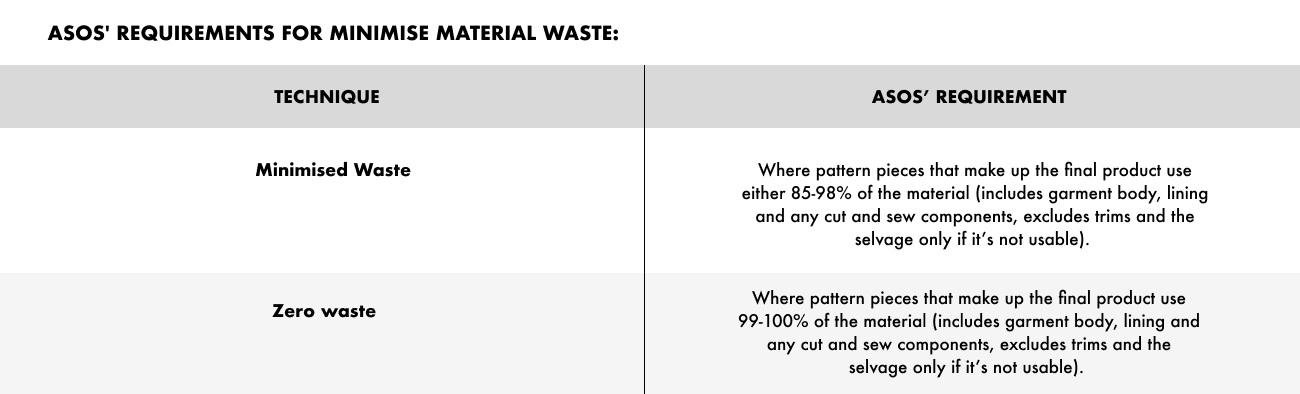

This optional technique specifically focuses on reducing material waste in production. This can be done by minimising or eliminating the material waste offcuts during cutting and sewing of a product through minimised waste or zero waste pattern cutting, which is where pattern pieces that make up the final product use either 85-98% (minimised waste) or 99-100% (zero waste) of the material. In the Textiles 2030 Circular Design Toolkit, it highlights that material waste is created at every stage of the supply chain, with 17.5% of material loss attributed to the product assembly phase of production (13), therefore this ASOS Circular Design technique focuses on 15% or less material loss. Digital 3D sampling can also be used to reduce physical sample waste (please note that using digital 3D sampling alone does not meet the requirements of this technique).

LIFECYCLE PHASE: IN USE

CIRCULAR DESIGN TECHNIQUE: DESIGN FOR PHYSICAL DURABILITY

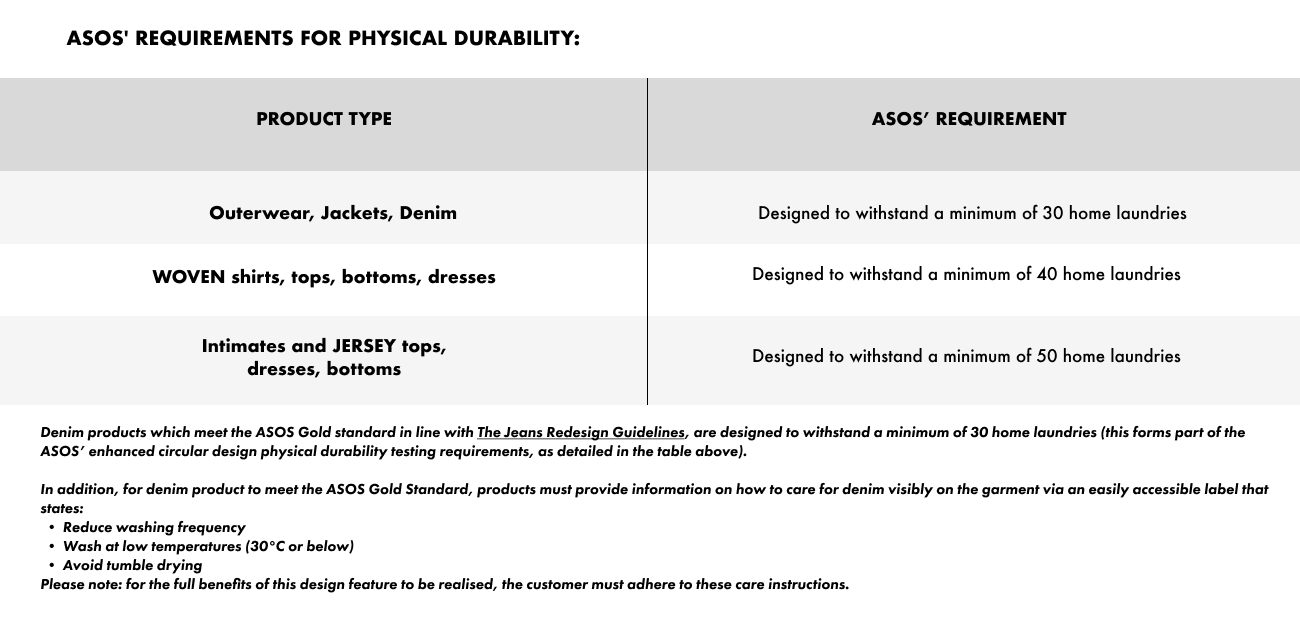

Textiles 2030 define durability as “the ability of a physical product to remain functional & relevant over time when faced with the challenges of normal operation” (14). To improve physical durability of products, they are designed to pass ASOS’ enhanced circular design physical durability testing requirements, which are informed by internal expertise,WRAP’s Clothing Longevity Protocol (see in particular the Test and Performance Guidelines in Appendix 2), The Jeans Redesign Guidelines and are validated by an external third-party lab. This includes passing specific International Organisation Standardisation (ISO) testing requirements. Note: ASOS are currently working on the WRAP Textiles 2030 x LITAC durability project, to input into updated durability standards for the fashion industry. Therefore, ASOS’ requirements could change as we further develop our durability standard.

We also consider closely how product construction techniques (such as on seams or stress points) can improve durability and help pass the testing requirements. Please note: for the benefits of this design feature to be realised, the customer should retain the product for as long as possible, as it has been designed with enhanced physical durability.

CIRCULAR DESIGN TECHNIQUE: DESIGN FOR VERSATILITY

This optional technique focuses on designing a product with increased versatility, so it can be reused, or used by different customers over its active life. This can include, but is not limited to, the following: unisex, adjustable size, multifunctional, reversible. To meet this technique, the product should have at least two marketable ways in which it can be worn or transformed OR the product can be worn by at least two different customers. Please note: for the benefits of this design feature to be realised, the customer needs to understand and use this feature.

LIFECYCLE PHASE: AFTER USE

CIRCULAR DESIGN TECHNIQUE: DESIGN FOR RECYCLABILITY

This technique focuses on designing products to maximise the amount of material that can be recycled after use (with currently available recycling technology). Please note: for the benefits of this design feature to be realised, the customer must recycle the product correctly. More information about your local recycling options can be found here: https://www.recyclenow.com/recycle-an-item/clothing-textiles?utm_source=loveyourclothes

When designing for recycling (using current technologies), the main considerations can include, but are not limited to: the main fibre in the product, trims and fastenings, construction techniques, dyes, prints, finishes.

Many products include elements or hard points (like fasteners, buttons or zips) that can disrupt the recycling process. These 'disruptors' have to be removed before the product can be recycled. So, to meet this technique, ASOS’ preference is to design to eliminate, reduce or substitute disruptors for another material, however this is not always possible. If none of these is viable, as a final resort, we design products that can be disassembled before recycling. This option relies on the customer taking the product to a valid recycling point, and the relevant recycler then taking responsibility for disassembling the product before recycling.

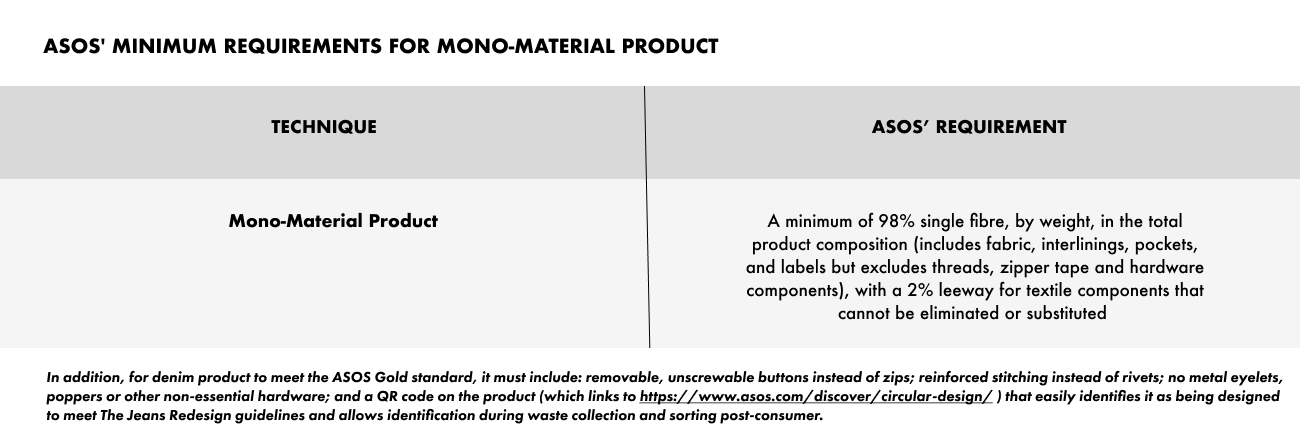

Recycling technologies are constantly developing and scaling. Currently, the majority of larger scale mechanical and chemical recyclers only accept mono-material fibres (with a small % allowed for ‘contaminants’ that don’t match the main fibre), therefore to meet this technique, ASOS requires products to have a minimum of 98% single fibre by weight in the total product composition (includes fabric, interlinings, pockets, and labels but excludes threads, zipper tape and hardware components), with a 2% leeway for textile components that cannot be eliminated or substituted. Look out for the product composition listed in the ‘About Me’ drop down on product page and on the product care label.

References

(1) Textiles 2030, Circular Design Toolkit:And introduction to design for circularity, page 10

(2) Textiles 2030, Circular Design Toolkit: And introduction to design for circularity, page 13

(3) The Ellen MacArthur Foundation

(4) Textiles 2030, Circular Design Toolkit: An introduction to design for circularity page 2

(5) Textiles 2030, Circular Design Toolkit, an introduction to design for circularity, page 90

(6) Textiles 2030, Circular Design Toolkit, an introduction to design for circularity, page 23

(7) https://textileexchange.org/app/uploads/2021/02/Global-Recycled-Standard-v4.0.pdft

(8) Textiles 2030, Circular Design Toolkit, an introduction to design for circularity, page 90

(9) Textiles 2030, Circular Design Toolkit, an introduction to design for circularity, page 89

(10) The Jeans Redesign guidelines, Appendix 1 Common definitions for The Jeans Redesign

(11) https://www.roadmaptozero.com/

(12) https://www.roadmaptozero.com/post/zdhc-wastewater-guidelines-v2-1-update-and-release

(13) Textiles 2030, Circular Design Toolkit , an introduction to design for circularity, page 42 (source: WRAP, 2021, Textiles 2030 Footprint Tool data)

(14) Textiles 2030, Circular Design Toolkit, an introduction to design for circularity, page 88